operate a skid steer with bad throttle actuator What to Do if The Actuator Calibration Doesn’t Work. If it does fail, you will need to investigate why. You may find trash in the spool, a bad actuator, bad spring or end cap, a problem in the . Each compact excavator we build is compatible with specialized attachments engineered to push your performance to new heights. Many models can be configured with industry-exclusive features – including the unique Pro Clamp™ system, Hydraulic X-Change™, and the extendable arm and depth check system.

0 · youtube skid steer actuator

1 · skid steer throttle settings

2 · skid steer throttle performance

3 · skid steer throttle high

4 · skid steer s185 full throttle

5 · skid steer full throttle review

6 · skid steer full throttle problems

7 · full throttle skid steering

Bulk Density (gr/cc) Downer Soil 1 1.2 1.4 1.6 1.8 2 4 6 8 10 12 14 16 18 20 22 24 Depth (inches) Bulk Density (gr/cc) The Compaction of Urban Soils M any professionals have an interest in the compaction of urban soils. For example, a structural engineer may need to increase compaction to provide a stable foundation for a road or building.

They tell me the new Tier 4 engines require to be run at full throttle when a sensor collects a certain amount of carbon from exhaust gases. I have run mine at full throttle in high range, to move from one place to another when it is too close to load up and haul, but so far I . Skid steers should have a decellerator like a dozer seeing as most new skids don't use yankem sticks. If skid steers had a transmission with gears like a loader or rubber tired . I'm use to the hydrostatic drive pump being a seperate unit, and the hydraulic pump being of the fixed variety(like mine) but possibly feeding the hydrostat unit, with two drive . If a machine has a throttle pedal, then surely it was designed for use when doing finesse work, like the CAT skid steer and CASE 450 and 550 dozers.

What to Do if The Actuator Calibration Doesn’t Work. If it does fail, you will need to investigate why. You may find trash in the spool, a bad actuator, bad spring or end cap, a problem in the .0.00K+0.00

9.009.959.00

.00 Learn the basics of how to operate a skid steer, a compact, maneuverable machine for various tasks. Find out the safety precautions, controls, attachments, and troubleshooting . To keep your skid steer operating at its best, you’ll want to pay close attention to the skid steer’s engine, hydraulic system and control system. Below are some of the top skid .

Learn how to rent, haul and operate a skid steer properly with tips and advice from Family Handyman. Find out which type of machine to choose, how to avoid accidents and . Learn how to safely and efficiently operate a skid steer with this comprehensive guide. Find out how to familiarize yourself with the controls, move forward and backward, . Case SV300 (Hours 2,567) skid steer will crank but will not start and will show no signs of wanting to start even with starting fluid . A 3835 code (throttle valve actuator power . They tell me the new Tier 4 engines require to be run at full throttle when a sensor collects a certain amount of carbon from exhaust gases. I have run mine at full throttle in high range, to move from one place to another when it is too close to load up and haul, but so far I haven't needed full throttle for any work I've done with it.

youtube skid steer actuator

Skid steers should have a decellerator like a dozer seeing as most new skids don't use yankem sticks. If skid steers had a transmission with gears like a loader or rubber tired backhoe they could make it so you can have variable throttle positions while travelling. Some actuators can be repaired but will need to be manually calibrated after doing so. The most common issues are, wiring, motor brushes, and actuator bearing failure." The video is presented well and he covers all three types of actuators currently in use. Run it hard, but throttle it back for a little bit at the end before shutting it down. As your machine runs an air cooled engine it should be run at a reasonable speed, not flat out, but i would say 3/4 or full if you are doing serious digging. I'm use to the hydrostatic drive pump being a seperate unit, and the hydraulic pump being of the fixed variety(like mine) but possibly feeding the hydrostat unit, with two drive motors, and every control being manuel.

If a machine has a throttle pedal, then surely it was designed for use when doing finesse work, like the CAT skid steer and CASE 450 and 550 dozers.

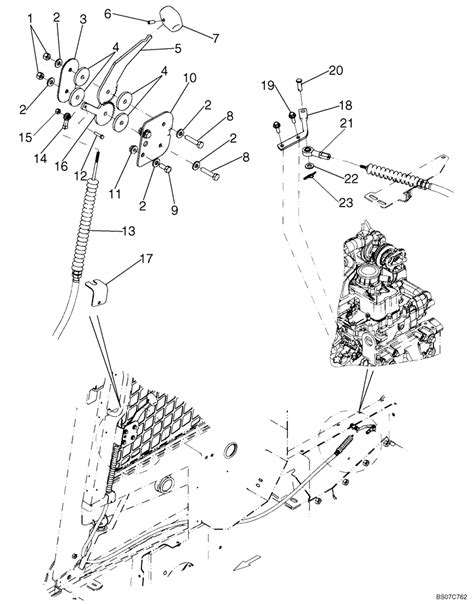

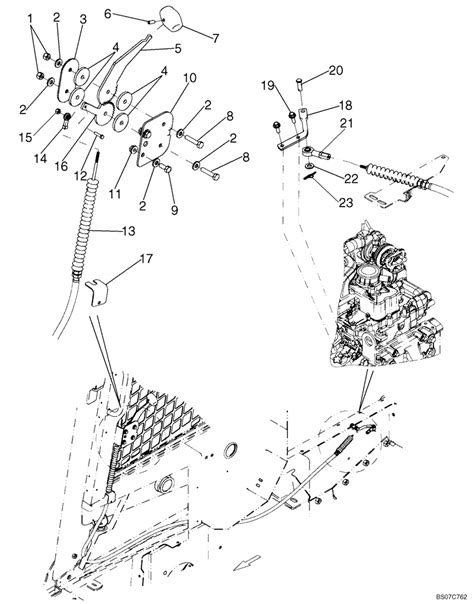

What to Do if The Actuator Calibration Doesn’t Work. If it does fail, you will need to investigate why. You may find trash in the spool, a bad actuator, bad spring or end cap, a problem in the harness, or possibly even a bad controller.

Learn the basics of how to operate a skid steer, a compact, maneuverable machine for various tasks. Find out the safety precautions, controls, attachments, and troubleshooting tips in this guide. To keep your skid steer operating at its best, you’ll want to pay close attention to the skid steer’s engine, hydraulic system and control system. Below are some of the top skid steer issues you may face within these categories and the ways you can check for them:

Remove the actuator bolts, pull it out and remove the detent pin. When you pull the actuator, the screw should extend smoothly and you should hear a nice smooth gear whine as you pull it out while the screw is attached to the spool. Any . They tell me the new Tier 4 engines require to be run at full throttle when a sensor collects a certain amount of carbon from exhaust gases. I have run mine at full throttle in high range, to move from one place to another when it is too close to load up and haul, but so far I haven't needed full throttle for any work I've done with it.

Skid steers should have a decellerator like a dozer seeing as most new skids don't use yankem sticks. If skid steers had a transmission with gears like a loader or rubber tired backhoe they could make it so you can have variable throttle positions while travelling.

Some actuators can be repaired but will need to be manually calibrated after doing so. The most common issues are, wiring, motor brushes, and actuator bearing failure." The video is presented well and he covers all three types of actuators currently in use.

Run it hard, but throttle it back for a little bit at the end before shutting it down. As your machine runs an air cooled engine it should be run at a reasonable speed, not flat out, but i would say 3/4 or full if you are doing serious digging. I'm use to the hydrostatic drive pump being a seperate unit, and the hydraulic pump being of the fixed variety(like mine) but possibly feeding the hydrostat unit, with two drive motors, and every control being manuel. If a machine has a throttle pedal, then surely it was designed for use when doing finesse work, like the CAT skid steer and CASE 450 and 550 dozers.

What to Do if The Actuator Calibration Doesn’t Work. If it does fail, you will need to investigate why. You may find trash in the spool, a bad actuator, bad spring or end cap, a problem in the harness, or possibly even a bad controller. Learn the basics of how to operate a skid steer, a compact, maneuverable machine for various tasks. Find out the safety precautions, controls, attachments, and troubleshooting tips in this guide.

To keep your skid steer operating at its best, you’ll want to pay close attention to the skid steer’s engine, hydraulic system and control system. Below are some of the top skid steer issues you may face within these categories and the ways you can check for them:

caterpillar 252b skid steer for sale

skid steer throttle settings

Fuel consumption is a critical aspect to bear in mind when you're running any construction equipment, primarily an excavator. Various factors influence fuel usage, and following the guidelines given here can help minimize fuel burn and lower the cost of your . See more

operate a skid steer with bad throttle actuator|skid steer throttle performance