skid steer lug torque I looked in the service manual and could not find the torque for the wheel lugs nuts and if I need to tighten in any specific order. Or can I just tighten in a circle with my cordless . Buy 36" Mini Excavator Bucket for Caterpillar Model CAT305 Mini Excavator with 45mm Pins (Pins Included): Spare & Replacement Parts - Amazon.com FREE DELIVERY possible on eligible purchases

0 · wheel stud torque size

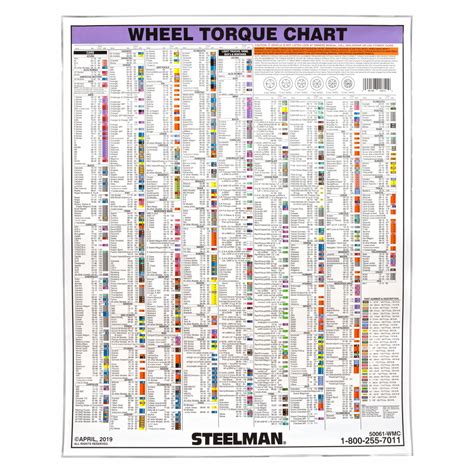

1 · skidsteer lug nut torque chart

2 · skidsteer 843 wheel lug nut torque

3 · s250 lug nuts torque

4 · bobcat wheel lug nuts torque

5 · bobcat 843 wheel lug torque

The Caterpillar 302.5 Mini Excavator is a versatile and powerful machine designed for a variety of excavation and construction tasks. With a compact size and exceptional maneuverability, this.

Anybody know the proper lug nut torques for a Bobcat A300 or 9/16" lugs? I have searched the forum and came up with anywhere from 105-160 ft-lbs. This is a huge discrepancy.I looked in the service manual and could not find the torque for the wheel lugs nuts and if I n.When working on cars, wheel torque is much more important because uneven torquing can . What is the correct torque spec for lug nuts on an S250? I'd imagine same for most other models as well. I am finding everything from 120 ft lbs to 320.

I looked in the service manual and could not find the torque for the wheel lugs nuts and if I need to tighten in any specific order. Or can I just tighten in a circle with my cordless .Find the torque specifications for different wheel stud sizes, lug nut types, wheel sizes and types, and wheel materials. The chart shows the torque values in ft.-lb. for steel and aluminum wheels.

Skid Steer SAE Rated Operating Capacities 240 681 kg (1,500 lbs.) 250 794 kg (1,750 lbs.) Ground Speed . Airboss Altrakka X-tra Lug NA 10.0 x 20.5 - Titan LSW "Grizzly" 310 kPa (45 .

It is extremely important to maintain proper wheel mounting torque limits on your trailer axle. Use of torque wrenches will ensure proper torque limits are applied to wheel mounting lug nuts. torque settings for the following: bolts, nuts, plugs, fittings, and clamps. Exceptions to these torques are given in the Service Manual, if necessary. Be sure to use a torque wrench . When working on cars, wheel torque is much more important because uneven torquing can warp brake rotors. For cars I use torque sticks, but on a skidsteer, good and tight .Learn how to prevent loose and cracked wheels and wheel end components by following the manufacturer's instructions for torque and re-torque. See the recommended practice for wheel .

Learn how to adjust the wheel bearing end play of 0.001” to 0.005” (.025 mm to .127 mm) for steer, drive and trailer axle assemblies on Class 6, 7 and 8 trucks. Follow the step-by-step . Anybody know the proper lug nut torques for a Bobcat A300 or 9/16" lugs? I have searched the forum and came up with anywhere from 105-160 ft-lbs. This is a huge discrepancy. What is the correct torque spec for lug nuts on an S250? I'd imagine same for most other models as well. I am finding everything from 120 ft lbs to 320. I looked in the service manual and could not find the torque for the wheel lugs nuts and if I need to tighten in any specific order. Or can I just tighten in a circle with my cordless impact and call it a day.

Find the torque specifications for different wheel stud sizes, lug nut types, wheel sizes and types, and wheel materials. The chart shows the torque values in ft.-lb. for steel and aluminum wheels.

Skid Steer SAE Rated Operating Capacities 240 681 kg (1,500 lbs.) 250 794 kg (1,750 lbs.) Ground Speed . Airboss Altrakka X-tra Lug NA 10.0 x 20.5 - Titan LSW "Grizzly" 310 kPa (45 psi) . Tube Nut/Swivel Nut Torque Bulkhead Locknut Torque Thread Size Straight Fitting or Locknut Torque mm Dash Size in. mmIt is extremely important to maintain proper wheel mounting torque limits on your trailer axle. Use of torque wrenches will ensure proper torque limits are applied to wheel mounting lug nuts. torque settings for the following: bolts, nuts, plugs, fittings, and clamps. Exceptions to these torques are given in the Service Manual, if necessary. Be sure to use a torque wrench that has the proper range. Torque wrenches must be used properly in order to ensure that the correct torque is applied. Always use a smooth pull for torque . When working on cars, wheel torque is much more important because uneven torquing can warp brake rotors. For cars I use torque sticks, but on a skidsteer, good and tight is good. Get a good mid level impact good for 500 lbs ft and you will be good to go.

Learn how to prevent loose and cracked wheels and wheel end components by following the manufacturer's instructions for torque and re-torque. See the recommended practice for wheel studs, nuts, and bolt holes, and the signs of low clamping force.Learn how to adjust the wheel bearing end play of 0.001” to 0.005” (.025 mm to .127 mm) for steer, drive and trailer axle assemblies on Class 6, 7 and 8 trucks. Follow the step-by-step instructions for different axle types, threads per inch and torque specifications. Anybody know the proper lug nut torques for a Bobcat A300 or 9/16" lugs? I have searched the forum and came up with anywhere from 105-160 ft-lbs. This is a huge discrepancy. What is the correct torque spec for lug nuts on an S250? I'd imagine same for most other models as well. I am finding everything from 120 ft lbs to 320.

I looked in the service manual and could not find the torque for the wheel lugs nuts and if I need to tighten in any specific order. Or can I just tighten in a circle with my cordless impact and call it a day.Find the torque specifications for different wheel stud sizes, lug nut types, wheel sizes and types, and wheel materials. The chart shows the torque values in ft.-lb. for steel and aluminum wheels.

Skid Steer SAE Rated Operating Capacities 240 681 kg (1,500 lbs.) 250 794 kg (1,750 lbs.) Ground Speed . Airboss Altrakka X-tra Lug NA 10.0 x 20.5 - Titan LSW "Grizzly" 310 kPa (45 psi) . Tube Nut/Swivel Nut Torque Bulkhead Locknut Torque Thread Size Straight Fitting or Locknut Torque mm Dash Size in. mm

It is extremely important to maintain proper wheel mounting torque limits on your trailer axle. Use of torque wrenches will ensure proper torque limits are applied to wheel mounting lug nuts.

torque settings for the following: bolts, nuts, plugs, fittings, and clamps. Exceptions to these torques are given in the Service Manual, if necessary. Be sure to use a torque wrench that has the proper range. Torque wrenches must be used properly in order to ensure that the correct torque is applied. Always use a smooth pull for torque .

When working on cars, wheel torque is much more important because uneven torquing can warp brake rotors. For cars I use torque sticks, but on a skidsteer, good and tight is good. Get a good mid level impact good for 500 lbs ft and you will be good to go.Learn how to prevent loose and cracked wheels and wheel end components by following the manufacturer's instructions for torque and re-torque. See the recommended practice for wheel studs, nuts, and bolt holes, and the signs of low clamping force.

12-16.5 skid steer tires maximum

wheel stud torque size

skidsteer lug nut torque chart

You can find walk behind mini excavators for sale in California for around $2,500, while larger mini excavator sales in California can cost closer to $100,000. Prices depend on size of the machine, horsepower, features, manufacturer, and digging depth.Up to $8,000 Cash Back on Mini Excavators Experience the efficiency of our mini excavators both on the jobsite and your bottom line with up to $8,000 cash back or 0% financing for up to 60 months. Hurry, offer ends November 30, 2024.

skid steer lug torque|skidsteer lug nut torque chart