drilling milling Mill drills are benchtop machines that can both drill holes and remove material from the surface . Find mini excavators for rent in various sizes, power levels and applications at The Cat Rental Store. Compare prices, features and benefits of different models and get a quote online.

0 · types of milling operations

1 · milling operation on drilling machine

2 · milling drilling machine for sale

3 · harbor freight milling drilling machine

4 · drilling milling machine

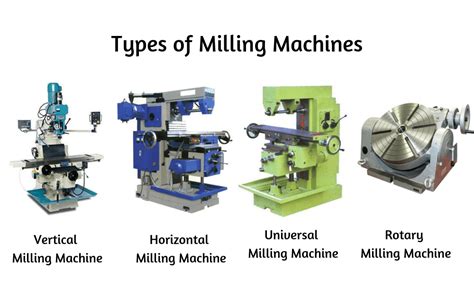

5 · different types of milling

6 · difference between drilling and milling

7 · best drilling milling machine

How much a mini excavator can dig in a day depends on several factors, such as the size of the excavator, the soil conditions and the desired depth. As a general rule of thumb, .

If you’re new to the industry or you’re trying to figure out which machine you should use for your next project, you’re in the right place. The primary functions are alike, and both of them can be useful for a variety of situations. There’s no doubt that you’ll have more than enough possible projects regardless of which . See moreSome people prefer one over the other, and for good reasons. Milling machines might seem like an obvious choice, but we haven’t gotten into . See moreWhether you’re choosing a drill press or a milling machine, both of them are excellent investments. The usefulness is boundless, especially if your job requires you to use one of them on a . See moreMill drills are benchtop machines that can both drill holes and remove material from the surface .

Learn the main differences between milling and drilling machines, such as cutting directions, speed, precision, and size. Find out the pros and cons of each machine and which one you should choose for your project.Mill drills are benchtop machines that can both drill holes and remove material from the surface of a workpiece in light milling tasks. Browse JET Tools' selection of mill drills with different features, sizes and prices.Learn how drilling and milling differ in their methods, tools, applications, and outcomes. Drilling creates cylindrical holes, while milling produces various shapes and contours in materials. The key difference between drilling and milling lies in the method of material removal. Drilling focuses on creating cylindrical holes using a rotating drill bit, whereas milling removes material by rotating a cutting tool across the workpiece surface.

Compare Differences Between CNC Milling and Drilling in Detail. These two CNC processes are renowned for their exceptional machining capabilities in different domains. They both have similar machine setups, precision, and control mechanisms. But what is the difference between milling and drilling? With no doubt, the milling vs drilling process works almost the same way and their functions are nothing short of being similar. Of all these similarities, the most valid one is that while drilling works on all surfaces, milling can only be carried out on metals. Learn the differences and similarities between drill presses and milling machines, and how to choose the best tool for your metalworking needs. Compare functions, axes of movements, accuracy, size, price, pros and cons of each machine. When running a job with thousands of similar-sized holes in it, drilling is clearly the right way. However, for a wide variety of holes, and some extra tool .

Choosing the right mill drill is crucial for achieving efficient and precise machining results. By considering factors such as machine type, features, built quality, precision, and safety you can make informed decisions that meet any kind of specific requirements a job may entail. Learn the key differences between milling and drilling, two subtractive machining processes, and between milling machine and drill press. Compare their capabilities, speed, surface quality, cutting tool, machine, working principle, feed, and contact with workpiece.

Learn the main differences between milling and drilling machines, such as cutting directions, speed, precision, and size. Find out the pros and cons of each machine and which one you should choose for your project.Mill drills are benchtop machines that can both drill holes and remove material from the surface of a workpiece in light milling tasks. Browse JET Tools' selection of mill drills with different features, sizes and prices.Learn how drilling and milling differ in their methods, tools, applications, and outcomes. Drilling creates cylindrical holes, while milling produces various shapes and contours in materials. The key difference between drilling and milling lies in the method of material removal. Drilling focuses on creating cylindrical holes using a rotating drill bit, whereas milling removes material by rotating a cutting tool across the workpiece surface.

Compare Differences Between CNC Milling and Drilling in Detail. These two CNC processes are renowned for their exceptional machining capabilities in different domains. They both have similar machine setups, precision, and control mechanisms. But what is the difference between milling and drilling? With no doubt, the milling vs drilling process works almost the same way and their functions are nothing short of being similar. Of all these similarities, the most valid one is that while drilling works on all surfaces, milling can only be carried out on metals. Learn the differences and similarities between drill presses and milling machines, and how to choose the best tool for your metalworking needs. Compare functions, axes of movements, accuracy, size, price, pros and cons of each machine.

When running a job with thousands of similar-sized holes in it, drilling is clearly the right way. However, for a wide variety of holes, and some extra tool .Choosing the right mill drill is crucial for achieving efficient and precise machining results. By considering factors such as machine type, features, built quality, precision, and safety you can make informed decisions that meet any kind of specific requirements a job may entail.

new holland tractor mini excavator sizes

types of milling operations

milling operation on drilling machine

milling drilling machine for sale

Hitachi ZX26U-5 Mini Excavator. Imperial Metric. Units. Dimensions. Boom/Stick Option (Hex) 1 . I Max Cutting Height. 14.7 ft in. M Max Digging Depth. 8.6 ft in. Boom/Stick Option (Hex) 1. 1.17-m (3 ft. 10 in) Standard Arm - Canopy. Max.Dumping Height. 10.6 ft in. Max Digging Reach. 15.2 ft in. Minimum Swing Radius. 75.6 in.

drilling milling|difference between drilling and milling