skid steer final drive components Keep that skid steer loader running efficiently with best in class reman hydraulic motors from Texas Final Drive.. Check it out! Topics: Heavy Equipment 101 , Skid Steers , Excavators Bid on Mini (Up To 12,000 Lbs) Excavators at auction & win with AuctionTime. Find Mini (Up To 12,000 Lbs) Excavators at online auctions from AGROTK, MIVA, CATERPILLAR, and more

0 · how do final drives work

1 · final drives for excavators

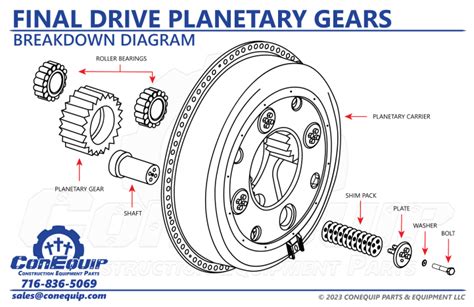

2 · final drive parts diagram

3 · final drive parts

4 · final drive assembly

5 · aftermarket final drives

Download the PDF brochure for the E26, a minimal tail-swing excavator with a long arm and a powerful engine. See the key specifications, capacities, dimensions, features and benefits of this versatile machine.

A final drive has two major components: a hydraulic motor and a gear reduction assembly. Hydraulic lines, sometimes up to five, deliver hydraulic oil into and out of the hydraulic portion of the final drive. Be sure not to mix up the feed and .

Learn how to identify and choose the right final drive for your skid steer loader or compact track loader. Compare new, reman, and used final drives and consider price, warranty, and shipping time. In simple terms, a final drive is the component of the machine’s powertrain that provides the necessary torque to move the tracks or wheels. Think of it as the last piece in the puzzle that translates engine power into movement.The housing on a final drive is the container that will enclose the final drive components, keep them in a lubricated environment, and connect to the machine. Because of the immense forces happening inside the final drive, the housing must be constructed to .Keep that skid steer loader running efficiently with best in class reman hydraulic motors from Texas Final Drive.. Check it out! Topics: Heavy Equipment 101 , Skid Steers , Excavators

Learn how to identify and fix the most common problems with final drives, the essential elements of tracked machines. Find out when to replace or repair your final drive and where to buy new ones. Learn what a final drive is and how it works on heavy construction equipment. See images of final drive parts, such as planetary gears, sun gear, ring gear, bearings, and seals.

The final drive motor provides the necessary power for movement and ensures smooth and controlled operation. It is designed to handle the demanding conditions and heavy loads that skid steers typically encounter on construction sites, farms, and other work environments. Learn about the two main types of final drives: hydraulic and electric, and how to choose the right one for your machinery. Compare their pros and cons, and consider factors such as load, torque, environment, quality, and cost.

Not all parts on a final drive were designed to be repaired. Some of them, like seals and gaskets, it makes sense to replace. Shafts and plates are slower wear parts that were designed to last longer.

A final drive has two major components: a hydraulic motor and a gear reduction assembly. Hydraulic lines, sometimes up to five, deliver hydraulic oil into and out of the hydraulic portion of the final drive. Be sure not to mix up the feed and . Learn how to identify and choose the right final drive for your skid steer loader or compact track loader. Compare new, reman, and used final drives and consider price, warranty, and shipping time. In simple terms, a final drive is the component of the machine’s powertrain that provides the necessary torque to move the tracks or wheels. Think of it as the last piece in the puzzle that translates engine power into movement.

The housing on a final drive is the container that will enclose the final drive components, keep them in a lubricated environment, and connect to the machine. Because of the immense forces happening inside the final drive, the housing must be constructed to .Keep that skid steer loader running efficiently with best in class reman hydraulic motors from Texas Final Drive.. Check it out! Topics: Heavy Equipment 101 , Skid Steers , Excavators Learn how to identify and fix the most common problems with final drives, the essential elements of tracked machines. Find out when to replace or repair your final drive and where to buy new ones. Learn what a final drive is and how it works on heavy construction equipment. See images of final drive parts, such as planetary gears, sun gear, ring gear, bearings, and seals.

The final drive motor provides the necessary power for movement and ensures smooth and controlled operation. It is designed to handle the demanding conditions and heavy loads that skid steers typically encounter on construction sites, farms, and other work environments. Learn about the two main types of final drives: hydraulic and electric, and how to choose the right one for your machinery. Compare their pros and cons, and consider factors such as load, torque, environment, quality, and cost.

how do final drives work

2006 bobcat 463 skid steer

This mini excavator rental has a compact and lightweight design, making it easy to safely load it onto a trailer. Our inventory includes models from top brands like Bobcat and Yanmar. Operating weight 2,000-2,999 lbs. depending on model. Standard tail swing. Up to 5'9" dig depth depending on model. Diesel power.

skid steer final drive components|aftermarket final drives